Product Description

| Description | Slab Panels System |

| Material | Panel Frame | High Strength Aluminum Alloy |

| Panel | Birch Ply |

| Panel size | Standard Panel Length | 600/900/1200/1800mm. Customized sizes acceptable. |

| Standard Panel Width | 600/900/1200mm. Customized sizes acceptable. |

Application

| Concrete Slab Pouring |

| Packaging | Pallet |

| Performance | Light weight. Great Strength. Modular Design. Fast to Assemble and Dismantle. |

| Category | Slab Panels System |

All KITSEN scaffolding and formwork products will be covered by RMB10,000,000.00 product liability insurance.

Slab Panels System

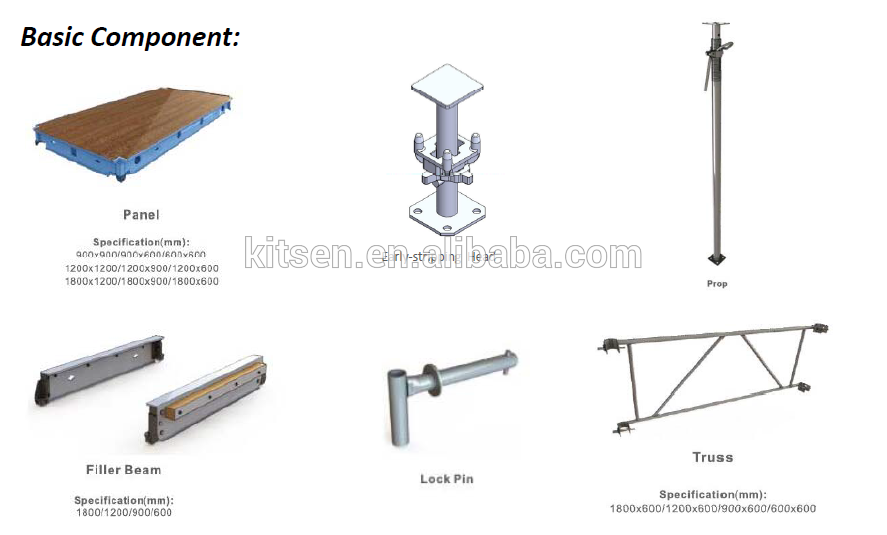

Kitsen Slab Panels System is an advanced aluminum panel-prop formwork system which allows early stripping operation.It provides a quick and fast forming solution to most concrete structures and meets the general requirements of different construction methods and conditions.

Features:

9 sizes of standard panels are available, and filler beam can be workable with flexible plywood to fit special structures.

Various solutions are suitable for different building structures.

5 days complete one floor’s construction (Saving labor & management cost)

Early-stripping system is applicable for saving building materials and working times in jobsite.

Simplified modular components for easier and faster erecting and dismantling.

One worker can install 27sqm per hour, and dismantle 54sqm per hour.

Stable with 6-direction locking restrictions.

Self-locking function for wind proof.

Tested and approved by Australian standard AS3610:1995.